The manufacturing plant is located in Bilimora, District Navsari, South Gujarat, India having proximity to the National Highway(NH-8), Bilimora Railway Station (Western Railway) and is situated at a distance of 200 kms for Mumbai & JNPT seaport. The company is currently engaged in contract manufacturing for well known Pharma companies and Exporters of India. The company exports to various countries around the world and has its ethical marketing in major states of India.

Our infrastructure is well equipped to produce quality formulations. We follow stringent quality practices as laid down by GMP standards and give meticulous attention on manufacturing, speed and capacity to ensure regular supply of quality pharmaceutical formulations to domestic and international markets. Formulations are manufactured in a controlled environment with a strict eye on technological updates in order to provide the best products. Our new facility of sterile Ophthalmic ointment & Lignocaine gel is WHO certified and is fully automatic plant.

We are fully equipped to handle contract manufacturing facilities with extensive experience of manufacturing custom formulations for pharmaceutical companies. The organization firmly believes in an approach of honesty and transparency.

Manufacturing Plant at Bilimora

| Team Strength | 50 |

| Administrative Staff Strength | 8 |

| Skilled Labour Strength | 11 |

| Unskilled Labour Strength | 31 |

| Plant Area | 14000 Sq. Ft. |

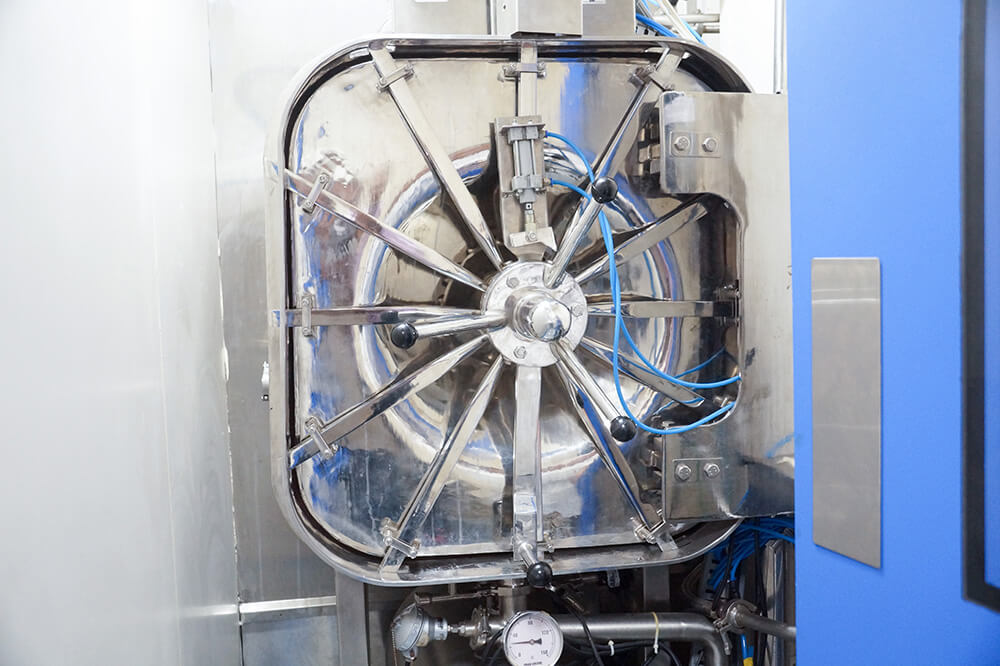

Sterile Ointment Department

Ophthalmic / Eye Ointments

Solid Oral Dosage Formulations Department

Tablet Section

Capsule Section

Liquid Oral Dosage Formulations Department

Syrup

Suspension

External Preparations Department

Ointment

Creams

Lotions, Liniments

Ear drops

Nasal drops

What make us Different ?

Well versed in handling contract manufacturing.

Large capacities to produce bulk quantities of Sterile Ointment, Liquid Oral Dosage Formulations, External Preparations, Solid Oral Dosage Formulations.

Commitment to Excellence and Quality.

Dedicated and committed team of professionals working in various capacities in departments such as Manufacturing, Administration, Quality Control and Formulations development.

Quality System

All the processes are backed by a sophisticated Quality Control System ensuring Quality product at each and every step - from acquiring of Raw materials to the Finished Formulations.

We make sure that the facilities and documentation procedures are maintained in accordance with WHO and GMP guidelines. Our rigorous quality assurance program ensures that every product bearing the name conforms to the highest standards of excellence.

The Manufacturing plant has machinery to manufacture high quality formulations which are supported by modern quality control instruments and testing equipments.

We appreciate the fact that quality is not a departmental obligation. It is the responsibility of each and everyone in the organization. We have developed a regimented quality control and assurance procedures. Raw materials are accepted for manufacturing only after it is found to be of specified grade by our quality control department.

Testing of raw materials, in process samples, semi finished and finished product sampling are carried out in the laboratory as per set standards.

Our quality control department is manned by experienced people having suitable experience and in-depth knowledge about the industry. Following analyses are carried out in-house:

Instrumental Analysis

Chemical Analysis

Microbiological and Sterility Testing

Packing Material Analysis

Future Plans :

The organization is fully geared up to face the challenges in the coming years and has plans to upgrade itself on technological and manpower front. These improvements will give us a strong hand in manufacturing, network establishment and new product development.

The organization has already received ophthalmic ointments & Lignocaine gel for WHO-GMP certification.

" We firmly stand by our commitment towards making this world a healthier place to live in."